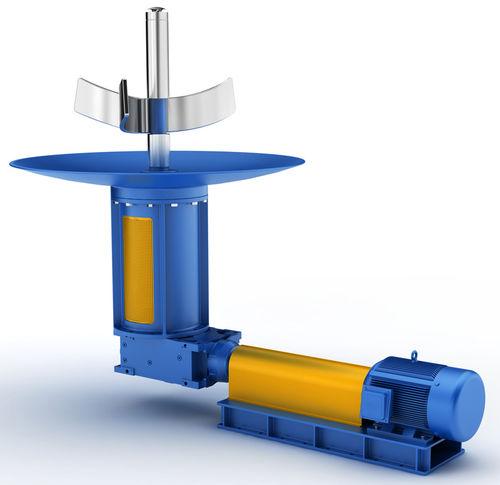

drum mixer / continuous / solid/liquid / horizontal

drum mixer / continuous / solid/liquid / horizontal

0,5 - 100 m3/h | HRM series

INO Group

-

Type:

drum

-

Batch/continuous:

continuous

-

Applications:

solid/liquid

-

Other characteristics:

horizontal, ring layer

-

Associated function:

with dryer

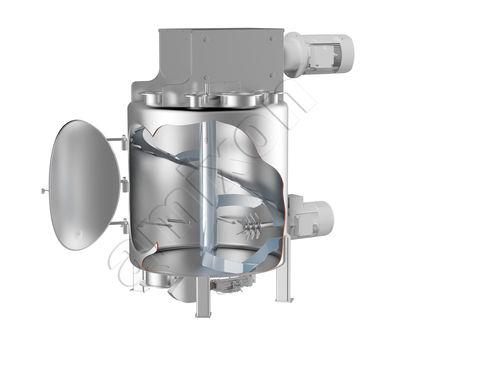

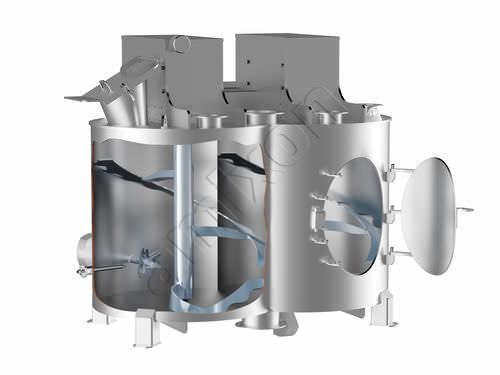

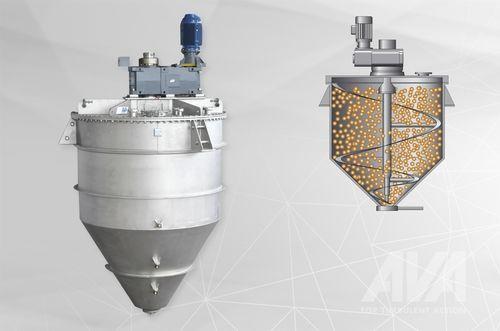

Ring Layer Mixer, horizontal mixer, horizontal dryer

Throughput performance: 0.5 – 100 m3/h

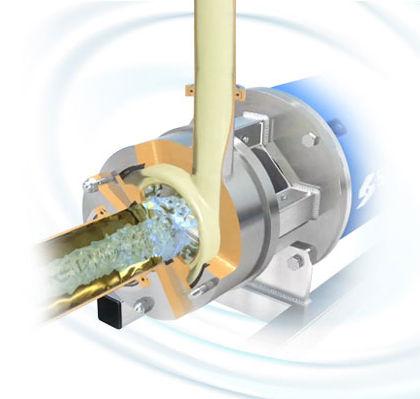

The mixing effect is based on a high circumferential speed of up to 50 m/sec. The resulting centrifugal force brings the product into a ring layer at the periphery of the mixing drum. The high speed difference between the rotating mixing elements and the mixing drum combined with the use of different mixing elements guarantees a very high mixing intensity.

AVA Test Centre

To gauge the efficiency of the AVA systems a modern test centre is available. Working with actual ingredients our process engineers help you to develop new products and to perform scale up tests for the design of production machines. There are also rental machines available to perform tests at the clients’ site

Fields of application

The AVA ring layer mixer is used for micro granulation in the chemical and pharma industry, mixing and drying

e. g. in the food industry and is also suitable for fibre processing, production of adhesive bonding compounds,

pastes and chipboards.

AVA provides you the right solution for your specific application.

Advantages

• Very intensive mixing

• Highly effective mixing of solids with fluids for the production of pastes

• Production of micro granules up to granules in the range of millimetres

• Optimal disintegration of fibre products

• Very short retention time - therefore small machine sizes with high throughput

• Optimal utilization of the installed power